When Winter Storms Become a Supply Chain Problem —

Winter storms in the United States are not new, but their impact on modern supply chains has grown significantly. Recent storms across the Midwest, Great Lakes, and Northeast regions disrupted road transport, air freight, and warehouse operations during the year-end and New Year period.

For many organizations, these disruptions resulted in delayed shipments, missed customer commitments, inventory shortages, and increased logistics costs. What makes these storms especially critical is their timing. The New Year is when businesses close holiday operations, review performance, and finalize Q1 supply and demand plans. Any disruption during this phase directly affects planning accuracy and operational stability.

These events highlight a key challenge in traditional supply chains: when disruptions occur, organizations often lack real-time visibility, coordinated planning, and fast decision-making capabilities. Without timely and accurate information, teams are forced to react manually, increasing both risk and cost.

This is where Oracle Supply Chain Management (SCM) becomes relevant—not as a reporting or monitoring tool, but as a system that supports decision-making and execution during disruptions.

How Oracle SCM Actually Helps During Winter Storm Disruptions —

Rather than offering generic benefits, Oracle SCM provides specific capabilities that help organizations respond to winter storm disruptions in a structured and controlled way.

1. Supply Chain Control Tower – Managing Visibility During Chaos —

a. Problem during storms:

During winter storms, companies often do not know which shipments are delayed, which suppliers are impacted, or which customer orders are at risk.

b. Oracle SCM capability:

The Supply Chain Control Tower provides real-time visibility across shipments, suppliers, inventory locations, and orders.

c. How it helps:

The system automatically detects delays and exceptions, highlights affected regions, and prioritizes critical orders that require immediate attention.

d. Business outcome:

Operations teams can focus on the most critical issues first, reducing confusion and avoiding reactive firefighting.

2. Demand & Supply Planning – Re-planning Instead of Guessing —

a. Problem during storms:

Sales and demand signals become unreliable due to delayed deliveries and missed holiday orders. This makes New Year and Q1 planning inaccurate.

b. Oracle SCM capability:

AI-driven Demand and Supply Planning allows organizations to re-forecast based on updated data and run multiple planning scenarios.

c. How it helps:

Planners can adjust demand forecasts, rebalance supply plans, and evaluate different recovery scenarios instead of relying on outdated assumptions.

d. Business outcome:

Organizations enter the New Year with more realistic plans, reducing the risk of overstocking or shortages.

3. Inventory Management – Balancing Stock Across Locations —

a. Problem during storms:

One warehouse may have excess inventory while another faces shortages due to transportation disruptions.

b. Oracle SCM capability:

Inventory Management provides visibility into inventory levels across all locations.

c. How it helps:

The system identifies alternative inventory sources and supports inter-warehouse transfers to maintain service levels.

d. Business outcome:

Customer deliveries continue with minimal disruption, and emergency procurement costs are avoided.

4. Transportation Management – Executing Under Constraints —

a. Problem during storms:

Road closures, carrier unavailability, and increased freight costs make standard transportation plans ineffective.

b. Oracle SCM capability:

Transportation Management enables real-time route replanning and carrier selection.

c. How it helps:

Logistics teams can evaluate alternate routes and carriers while balancing delivery priority and cost.

d. Business outcome:

Fewer missed deliveries and better control over logistics expenses during disruptions.

Key New Year Lessons and the Path Forward —

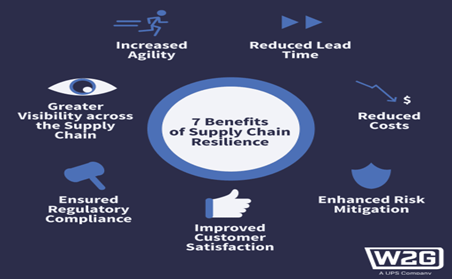

Recent winter storms offer valuable lessons for organizations planning the year ahead:

- Visibility is critical — You cannot manage what you cannot see

- Manual processes are insufficient in high-risk scenarios

- Resilience matters more than speed

- Technology is a strategic investment, not just an IT tool

companies that invest in resilient supply chains are better positioned to protect revenue, customer trust, and operational stability.

Conclusion: Starting the New Year with Control, Not Chaos —

Winter storms may be unavoidable, but supply chain chaos is not. As organizations move into a new year, the focus must shift from reactive recovery to proactive resilience.

With Oracle SCM, businesses can turn disruption into insight, uncertainty into preparedness, and challenges into competitive advantage.

The strongest supply chains are not built after the storm—but before it arrives.

– Gray Acumen